Leather product manufacturing enterprises need accurate time synchronization in the production process to ensure accurate coordination of various links and improve factory manufacturing efficiency. As an accurate time synchronization tool, synchronous clocks can provide reliable time benchmarks for leather product manufacturing enterprises. This article will introduce how to use synchronous clocks to improve the manufacturing efficiency of leather product manufacturing enterprises.

The role of synchronous clocks

A synchronous clock is a device used for time synchronization, which can obtain time information through a network connection and synchronize it to a local device. It can provide high-precision time benchmarks to ensure consistency among various devices at the same time point, avoiding errors caused by time differences. In leather product manufacturing enterprises, synchronous clocks can be applied to the following aspects:

Production process synchronization: During the production process, different equipment needs to coordinate and operate to complete the processing tasks of each link. Synchronous clocks can ensure that each device starts or ends tasks at the same time point, thereby improving production efficiency.

Data recording accuracy: For various process parameters, machine status, product information, etc., synchronous clocks can ensure that they are accurately recorded in the corresponding data system, ensuring the reliability and accuracy of the data.

Product traceability: Synchronous clocks can help record and identify the production time of each production batch, thus facilitating product traceability and management in the later stage.

Safety control: Some production processes require equipment to operate within strict time requirements, such as hazardous material manufacturing. Synchronous clocks can ensure that the device operates within a specified time period, thereby avoiding potential security risks.

Selection of synchronous clock

When choosing a synchronous clock, it is necessary to consider the specific needs of the enterprise. The following are some factors that need to be noted:

Accuracy: The accuracy of synchronous clocks is crucial, and it is required to provide high-precision time benchmarks to ensure accurate synchronization of production processes.

Reliability: Synchronous clocks need to be stable and reliable, able to maintain synchronization for a long time and avoid time drift.

Ease of use: Synchronous clocks need to be easy to install, configure, and use, minimizing the complexity of maintenance and operation.

Compatibility: The synchronous clock needs to be compatible with the existing network architecture to avoid being unable to use due to compatibility issues.

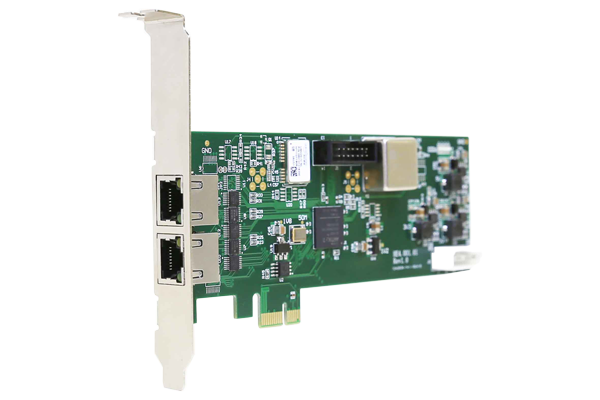

The Application and Advantages of GPS Beidou Synchronous Clock

GPS Beidou synchronous clock is a synchronous clock based on GPS and Beidou satellite systems, which can provide high-precision time and improve production efficiency

Leather product manufacturing enterprises can use synchronous clock systems to improve production efficiency. Here are some ways to achieve this goal:

4.1 Production scheduling

Synchronous clocks can be integrated with production scheduling software to ensure that workers always know where they should be and when to complete tasks. In addition, synchronous clocks can also avoid any production interruption or downtime by synchronizing all timing devices. This will ensure that all production departments work according to plan, thereby improving production efficiency.

4.2 Synchronous production line

On a production line, if each workstation is used for different times, it may lead to confusion and delays in the production process. Synchronous clocks can ensure that each workstation uses the same time, making the production process smoother and more efficient. For example, when manufacturing a leather bag, if the worker spends too much time at a certain stage, it may lead to delayed completion of subsequent processes. By synchronizing the clock, it can ensure that workers complete their work within the specified time, thereby ensuring the efficiency of the entire production process.

4.3 Control Inventory

Synchronous clocks can help businesses manage inventory and improve production efficiency. Inventory management typically involves multiple departments, including procurement, production, and sales. If the time of each department is different, it may lead to inventory problems, such as excessive or insufficient inventory. Synchronizing the clock ensures that all departments use the same time, thereby avoiding inventory management issues and improving production efficiency.

4.4 Fault prevention

Synchronous clocks can help businesses prevent failures and improve production efficiency. In a large manufacturing factory, there are many machines and equipment that require maintenance. If these devices are used for different times, it may lead to problems in maintenance and repair work. By synchronizing the clock, it can be ensured that each device uses the same time, making maintenance and repair work more orderly and efficient. This will help to avoid malfunctions and production downtime, thereby improving production efficiency.

In summary, synchronous clocks are very important for leather product manufacturing enterprises. It can help enterprises improve production efficiency, reduce production interruptions and downtime, improve product quality, avoid inventory problems, and prevent malfunctions. Therefore, leather product manufacturing enterprises should invest in synchronous clock systems and ensure that they can use and maintain these systems correctly.

上一篇:没有了 下一篇:Furniture Manufacturing Enterprise: Introduction to the Appl