With the continuous development of industrialization, the market competition in the metal product processing industry is becoming increasingly fierce, and enterprises need to continuously improve production efficiency and product quality to maintain competitiveness. Precision machines play a crucial role in production, and precise operating time and high-precision machine control are key factors to ensure product accuracy and quality. Therefore, in order to ensure the production efficiency and product quality of metal product processing plants, it is necessary to introduce synchronous clock technology.

This article will introduce the application of synchronous clocks in metal product processing factories and how to improve machine operation accuracy through synchronous clocks.

1、 The Application of Synchronous Clock in Metal Products Processing Plants

Improving the accuracy of machine operation

The metal product processing industry requires high-precision machine control, and synchronous clocks can provide a unified time benchmark to ensure the time synchronization accuracy of different machines. When the machine is running, synchronizing the clock can ensure that all machines run at the same clock, thereby avoiding problems such as inaccurate machine control and machine shutdown caused by time errors. By means of synchronous clock technology, the factory operation cost can be reduced, the product manufacturing efficiency can be improved, the Product defect rate can be reduced, and the product quality can be improved.

Improved production scheduling accuracy

In the metal product processing industry, production scheduling is very important. By using synchronous clock technology, it is possible to ensure that all machines operate on a unified time benchmark, thereby ensuring the accuracy of production scheduling. Synchronous clocks can help factories timely understand the status of machines, optimize machine operation efficiency, optimize production planning, and improve the efficiency of production scheduling.

Product quality improvement

Synchronous clocks can effectively ensure the precise operation of machines, thereby avoiding the occurrence of production defects caused by time errors. By using a unified time benchmark and high-precision machine control, the accuracy and quality of products can be improved, and defects and scrap rates can be reduced.

2、 How to improve machine operation accuracy through synchronous clock synchronization

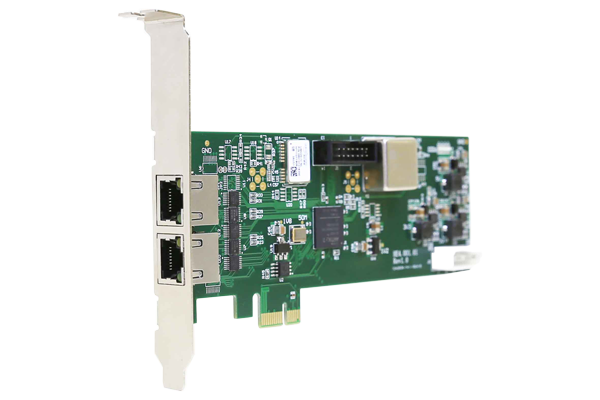

Using NTP Server

NTP server is a network server that can provide high-precision time synchronization. It obtains standard time signals through the internet and provides them to computers and devices in the local network. Metal product processing plants can achieve a unified time benchmark by using NTP servers, ensuring that all machines run at the same time, thereby improving machine operation accuracy. For metal product processing plants, synchronous clocks can improve machine operation accuracy, ensure accuracy and stability in the manufacturing process, and thereby improve production efficiency and product quality. Next, we will explore how to achieve this goal by synchronizing the clock.

Synchronize machine time

In the process of metal product processing, time synchronization of machines is very important. Because if the machine time is not synchronized, it can lead to time deviation between different machines, which affects the coordination and accuracy of the processing process. The use of NTP servers can help achieve machine time synchronization and ensure that the time of each machine is consistent.

Improve machine control accuracy

Synchronous clocks can provide accurate time benchmarks for machines, thereby improving machine control accuracy. The control system of the machine can accurately calculate the synchronization time, thereby accurately controlling the machine's operation and processing process, improving the accuracy and quality of processing.

Reduce machine malfunctions

The stability of machine operation is very important in the processing of metal products. Synchronizing the clock can avoid errors or malfunctions caused by the machine being out of sync with time. Because the control system of the machine can accurately calculate the synchronization time, thereby avoiding errors or malfunctions caused by time deviation.

Increase production efficiency

Synchronous clock can ensure the time synchronization and control accuracy of the machine, thereby improving production efficiency. Accurate time synchronization can enable coordinated operation between machines, thereby improving the efficiency of the entire processing process. Meanwhile, accurate control accuracy can reduce machining errors, improve machining speed and quality, and thus improve production efficiency.

Improve the automation level of manufacturing processes

Synchronous clocks can improve the automation of the manufacturing process. Accurate time synchronization and control accuracy can enable more coordinated operation between machines, thereby achieving automation and intelligence in the processing process. By using synchronous clocks, metal processing factories can improve the automation of machines, reduce manual intervention, and thereby improve production efficiency and manufacturing quality.

In short, synchronous clocks can help metal product processing plants improve machine operation accuracy, reduce machine failures, improve production efficiency and automation of the manufacturing process, thereby improving manufacturing quality and market competitiveness

上一篇:Food processing factory: How to use GPS Beidou synchronous 下一篇:没有了